Anycubic Kobra 3 V2 Combo 3D Printer

Anycubic Kobra 3 V2 Combo 3D Printer

Low stock: 5 left

Couldn't load pickup availability

Overview

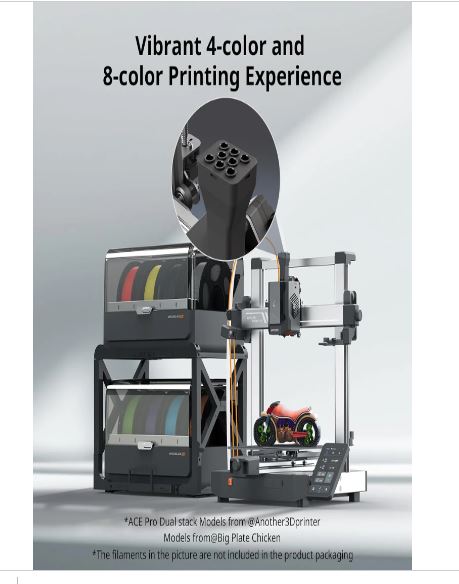

The Anycubic Kobra 3 V2 Combo is a high-speed, multi-colour capable FDM printer with a large build volume, designed for users wanting quicker prints, colour/multi-material options, and a lot of smart features. The “Combo” refers to the fact that it includes the ACE Pro module(s) that allow multi-colour/multi-filament printing (4-color, up to 8-color if two ACE Pros are used + the hub).

Product Description

A high-performance, feature-rich FDM 3D printer designed for speed, multi-colour capability, and versatile material use. Built for serious prototyping, creative design, and flexible, high throughput printing workflows.

Key Features & Technical Specifications

-

Build Volume: Approx. 255 × 255 × 260 mm — allows printing moderately large objects in one go without splitting parts.

-

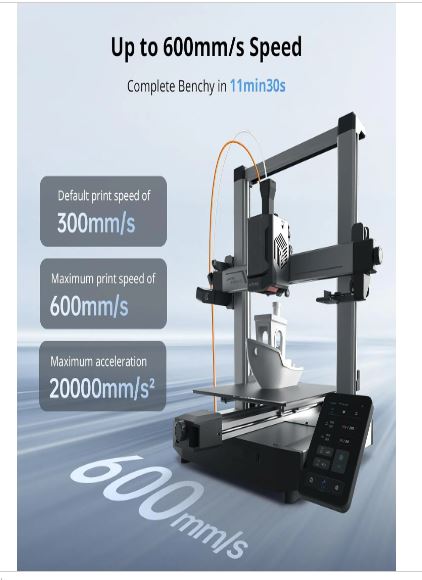

Print Speed & Acceleration:

-

Maximum travel speeds up to ~600 mm/s

-

Acceleration up to ~20,000 mm/s²

-

Recommended operational speed lower (for best surface quality and reliability)

-

-

Nozzle & Hotend:

-

Standard nozzle diameter: 0.40 mm, with options for 0.60 mm or 0.80 mm to trade detail vs. speed

-

Maximum hotend temperature: ~300 °C, allowing use of more advanced engineering filaments

-

-

Build Plate:

-

Heated bed with maximum temperature up to ~110 °C

-

Flexible or spring-steel plate with PEI (or equivalent) surface for good adhesion and easy part release

-

-

Multi-colour / Multi-filament Capability:

-

Enables printing with multiple filaments / colours via one or more filament-feeding modules

-

Supports a setup with additional filament ports or hubs to manage several spools

-

-

Filament Handling & Drying:

-

Built-in filament drying chamber or system maintained at moderate elevated temperature (≈ 35-55 °C) to reduce moisture issues

-

Filament run-out detection and retraction or pause-on-run-out features

-

-

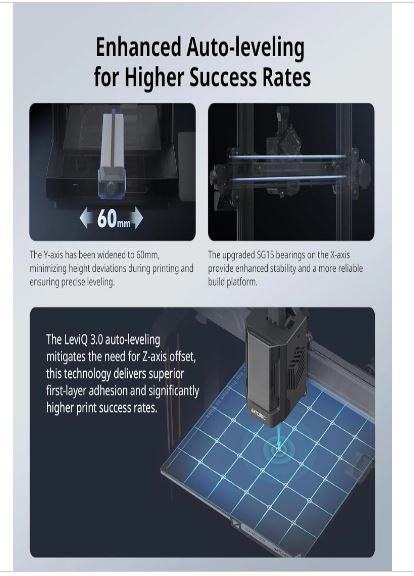

Auto-leveling & Frame Stability:

-

Automatic bed leveling system, reducing manual intervention

-

Reinforced frame / upgraded bearings on critical axes to minimize vibration/artifact at high speeds

-

Wider gantry or support in one or more axes to improve leveling consistency

-

-

Electrical & Power:

-

Single power input unit, combined printer + module draw possibly up to ~400 W under load

-

Compatible with typical mains supplies; ensure stable voltage and adequate ventilation

-

-

User Interface & Monitoring:

-

Touchscreen control panel (≈ 4-5 inch capacitive display) for job setup, adjustments, firmware updates

-

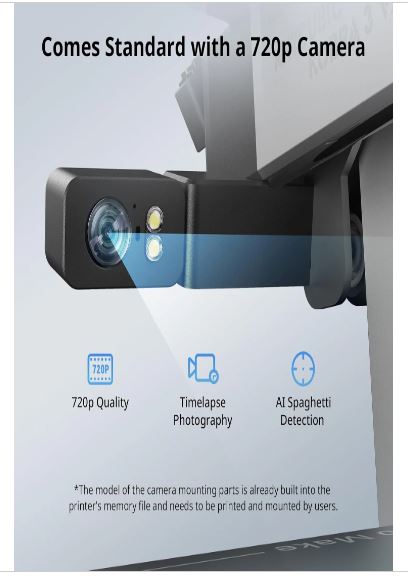

Integrated camera for print monitoring; potential for remote status viewing, time-lapse capture

-

-

Safety & Recovery Features:

-

Power-loss recovery (pauses print and resumes once power resumes)

-

Detection of filament issues (run-out, jam, entanglement)

-

Temperature protections for hotend / bed

-

-

Supported Filaments:

-

Standard materials: PLA, PETG, TPU (flexible filament)

-

With upgrade modules: ABS, ASA, PC, PA, PP, HIPS, etc. (depending on hotend grade, enclosure or ambient conditions)

-

-

Nozzle Options:

-

Standard fine nozzle (0.4 mm) for detail

-

Larger nozzles (0.6-0.8 mm) for faster printing and larger layer heights

-

-

Physical Characteristics:

-

Moderate footprint; heavy components if multi-filament module(s) attached

-

Packaging includes printer base, filament feeding module(s), spool hub(es), power supply, build plate, and accessories

-

Typical Operation Conditions & Trade-Offs

-

To maintain high print quality, speed, and accuracy, regular calibration is needed (bed leveling, checking belt tensions, etc.).

-

Fast printing tends to introduce artifacts like ringing or ghosting, especially on tall or detailed prints; slower speeds may be used when detail is important.

-

Multi-filament / colour printing increases complexity: oozing, colour bleed, nozzle purging, and filament transitions require tuning.

-

Environmental conditions (temperature, humidity, ventilation) play a significant role, particularly when printing materials sensitive to moisture or cooling quickly (ABS, ASA, Nylon, etc.).

Share

- Top Quality

- Best Price

- Fast Ship

Shipping Policy

Shipping Policy

- Shipping is calculated at time of checkout according to weight.

- Shipping Free on Orders above Rs. 3000/-

- For Further Details Visit- Shipping Terms

Return and Refund Policy

Return and Refund Policy

- Damage Claims: Video must be recorded while opening the delivered package in case of damage replacements.

- For further details please visit Return & Exchange Policy.